Z-Frame: A Safer Option Than Aluminum Horse Trailers

If you've owned a horse trailer for any length of time, you’ve probably faced the same frustrating trade-off: steel trailers that rust and require constant upkeep, or aluminum trailers that overheat and feel flimsy under pressure. Neither choice feels quite right... especially when you're thinking about your horse’s safety and comfort.

That’s the problem Brad Heath set out to solve. As founder of Double D Trailers and a longtime advocate for safer trailer designs, Brad spent years exploring materials that could offer the strength of steel, the rust resistance of aluminum, and none of the compromises.

The result is Z-Frame Technology: a high-tensile, zinc-infused material that’s engineered to stay strong, resist corrosion, and protect your horse in ways traditional frames can’t. On this page, we’ll walk you through how trailer construction has evolved, what makes Z-Frame different, and why it’s become the foundation for every trailer we build at Double D Trailers.

What Changed in Horse Trailer Construction?

Back in the 1950s, horse trailers were little more than angled iron and raw sheet metal, welded together, primed, and painted. But the steel used at the time rusted easily, and the welded joints allowed moisture to seep in — causing rapid oxidation. As Brad explains:

“Steel trailers of that era had weakly welded joints and no real way to seal off moisture. They started rusting the minute they left the shop.”

In the 1980s, manufacturers began experimenting with aluminum. It was lightweight, non-rusting, and shiny — and its higher cost gave it a reputation for being superior. But as the years went on, serious drawbacks became impossible to ignore.

But Were Aluminum Trailers Really Better?

Not exactly. Aluminum solved the rust problem, but introduced new risks:

-

Heat conduction that turns trailers into ovens

-

Weak structural integrity during collisions

-

Floors vulnerable to corrosion from urine

-

Dividers that twist and expose sharp edges

“Large horse trailer companies were quick to jump on the aluminum bandwagon,” Brad says. “But just because it’s expensive and shiny doesn’t mean it’s better. In fact, aluminum frames can be downright dangerous.”

Many manufacturers still use aluminum today — not because it’s best, but because retooling their entire operation is too costly. That’s why Double D Trailers took a different path.

The Dangers of Aluminum Trailers

1. Heat Buildup

Aluminum is a great heat conductor. On a sunny day, the roof can raise interior temperatures to over 130°F — putting your horse at serious risk of dehydration, heat stress, and panic.

2. Floor Failure

Horse urine is acidic and accelerates corrosion. Over time, even with mats, the floor can weaken enough for a horse’s hoof to punch through while in motion — often resulting in fatal injury.

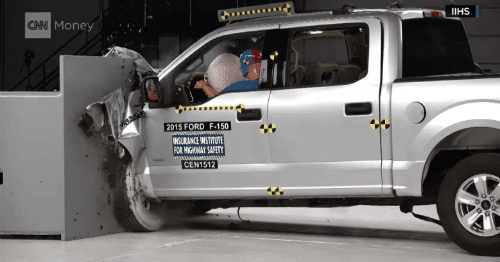

3. Structural Weakness

When Ford tested its all-aluminum F-150 SuperCab in a crash, the results were alarming. The front end crumpled like a soda can, the cabin was compromised, and the truck received one of the lowest possible safety ratings for its class.

“Aluminum just isn’t cut out for high-stress situations,” Brad said after reviewing the crash data. “It can’t take the same abuse that steel can.”

Horse trailers don’t undergo crash testing like cars do — but the lesson is clear: flimsy materials offer flimsy protection.

So What About Steel?

Modern steel trailers are far better than their 1950s counterparts, thanks to improved coatings and bonding techniques. Many brands today build with:

-

All-steel (affordable but still prone to rust at seams)

-

Steel frames with aluminum skin (better, but mismatched metals can create corrosion points)

-

Galvanneal skin on steel frame (a zinc-iron alloy that resists oxidation — used by Double D Trailers from 1997–2008)

Brad liked the strength of steel — but not the rust. And he knew aluminum was too weak. So in 2009, he began developing something better.

What Is Z-Frame Technology?

Z-Frame is a proprietary steel tubing infused with zinc and chromate, which creates a protective barrier against rust and heat transfer. This tubing forms the chassis and interior dividers of every Double D Trailer.

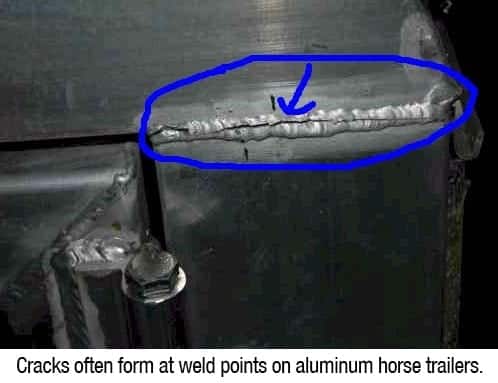

“The whole process behind our exclusive technology actually increases the tensile rating of the tubing — making it so much stronger than aluminum,” Brad says. “And it eliminates the issue of weld cracking that happens with aluminum over time.”

-

Stronger than traditional steel or aluminum

-

Lighter weight than steel due to thinner yet stronger tubing

-

Rust-proof from the inside out

-

Designed for safety, longevity, and comfort

To see how Z-Frame integrates into the full construction process — from welding to finishing — check out How Our Horse Trailers Are Built.

Did You Know?

Our gooseneck trailers and bumper pull trailers use exclusive Z-Frame® technology, stronger than steel, lighter than aluminum, and rust-free for life.

How Z-Frame Trailers Keep Horses Safer from Every Angle

The Z-Frame chassis is just the beginning. Every element of a Double D Trailer including the walls, roof, and floor, is designed to protect your horse from heat, noise, vibration, and impact.

Wall System

After the Z-Frame is built, the walls are added using a double-insulated system:

-

Galvalite skin — a material 5x stronger than aluminum

-

3M VHB bonding — a chemical adhesive that replaces rivets and screws

This fastener-free design allows the walls to flex naturally with temperature changes, which prevents warping, keeps moisture out, and eliminates rattling.

“It’s not just tape,” Brad explains. “This bonding is stronger than welds and flexible enough to handle road vibration without breaking down.”

Read More: Are Your Horse Trailer Walls Strong Enough?

SafeBump® Roof

The SafeBump® roof is a one-piece fiberglass composite that offers:

-

Impact protection if a horse rears

-

Seamless, leak-proof construction

-

Superior insulation compared to aluminum

Because it’s not metal, it reflects heat instead of absorbing it, helping the interior stay cooler, longer.

Learn more about roof safety here: What’s the Safest Roof Material for a Horse Trailer?

Floor System

Instead of heat-conductive aluminum, every trailer uses:

-

Rumber or treated wood flooring

-

Layers that absorb noise and vibration

-

Materials that resist urine corrosion and salt damage

The result is a cooler, quieter ride and a safer footing for your horses.

Considering flooring options? Pros and Cons of Rumber Flooring

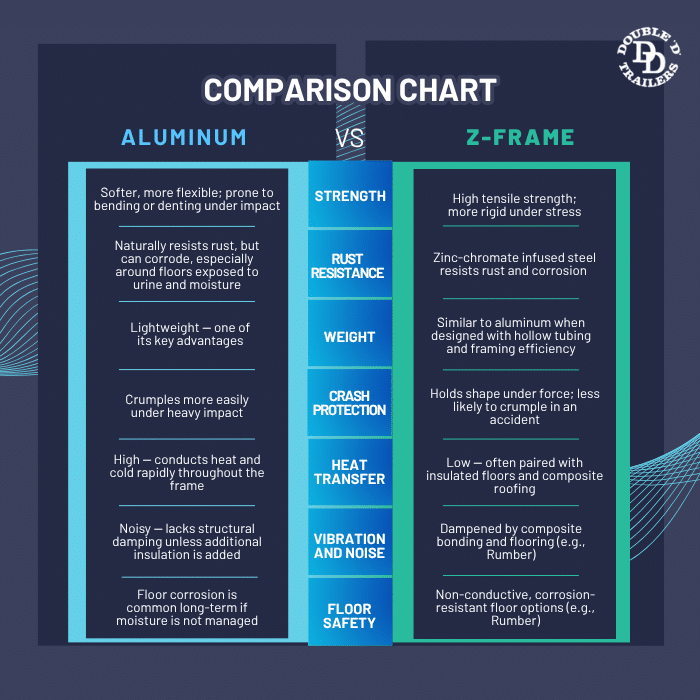

Z-Frame vs. Aluminum: Side-by-Side Comparison

Z-Frame isn’t just about materials, it’s about giving your horse the best possible protection in the event of a crash. To understand what can happen during a real trailer accident and why proper design matters, read our guide on horse trailer accident safety.

Why Z-Frame Is the Safest Option

- Stronger Than Aluminum

Z-Frame tubing has a higher tensile rating and doesn’t crack at weld points. -

Lighter Than Steel

Because the zinc alloy is stronger, thinner tubing can be used — reducing weight without compromising strength. -

Cooler, Quieter Rides

The combination of insulated floors, SafeBump roof, and rivet-free walls keeps the interior temperature down and your horse relaxed. -

Built to Last

In salt spray tests, Z-Frame outperforms hot-dipped and pre-galvanized steel by up to 3X.

“You get what you pay for in this industry,” Brad often says. “A less expensive trailer might seem like a deal — but it’ll cost you more in safety, repairs, and peace of mind.”

Real Customer Experience: Why Mike Switched to Z-Frame

“As a firefighter, I had an opportunity to attend a 3-day large animal rescue class. After seeing what an accident can do to an aluminum trailer, we thought it might be a good time to look at getting rid of the aluminum trailer. We started an extensive Internet search and all paths led us to Double D Trailers. We were particularly impressed with the Z-Frame and the SafeBump roof system. Even sitting out in the 100-degree Carolina sun, the interior stays much more comfortable compared to our previous metal-roofed trailer.”

— Mike, South Carolina

Watch Mike and Shelley's journey above. Z-Frame isn’t just theory — it’s protecting real horses, every day.

Want a Trailer That’s Safer by Design?

Every Double D Trailer is built on a Z-Frame foundation, because safety should never be optional. From bumper pull horse trailers to living quarters, or gooseneck models, every trailer is fully customizable and built using this exclusive, crash-resistant framing system — designed to protect your horse and give you peace of mind mile after mile.

Ready to start your build? Contact us to learn more or visit the Double D Trailers shop to browse custom options.

Schedule Your Free Video Consult Today!Frequently Asked Questions About Z-Frame Technology

What is Z-Frame made of?

Z-Frame is a proprietary steel tubing infused with zinc and chromate. This combination increases tensile strength, resists corrosion, and prevents heat transfer — making it ideal for horse trailer frames and dividers.

Is Z-Frame stronger than aluminum?

Yes. Z-Frame has a higher tensile strength than aluminum, meaning it holds its shape better under stress and won't twist, bend, or crack at weld points like aluminum often does.

Does Z-Frame rust like steel?

No. Thanks to the zinc-chromate infusion, Z-Frame resists oxidation and corrosion far better than traditional steel. It performs exceptionally well in salt spray tests and is built to last even in tough climates.

Is a Z-Frame trailer heavier than an aluminum trailer?

Surprisingly, no. Because Z-Frame is so strong, Double D Trailers can use thinner-gauge tubing to maintain strength without adding weight. Most Z-Frame trailers are within 80–100 lbs of their aluminum-frame equivalents.

What makes Z-Frame safer for my horse?

Z-Frame trailers are designed to reduce heat buildup, minimize vibration, and stay structurally sound in high-stress situations. Combined with the SafeBump® roof and Rumber flooring, Z-Frame gives your horse a cooler, quieter, and more secure ride.