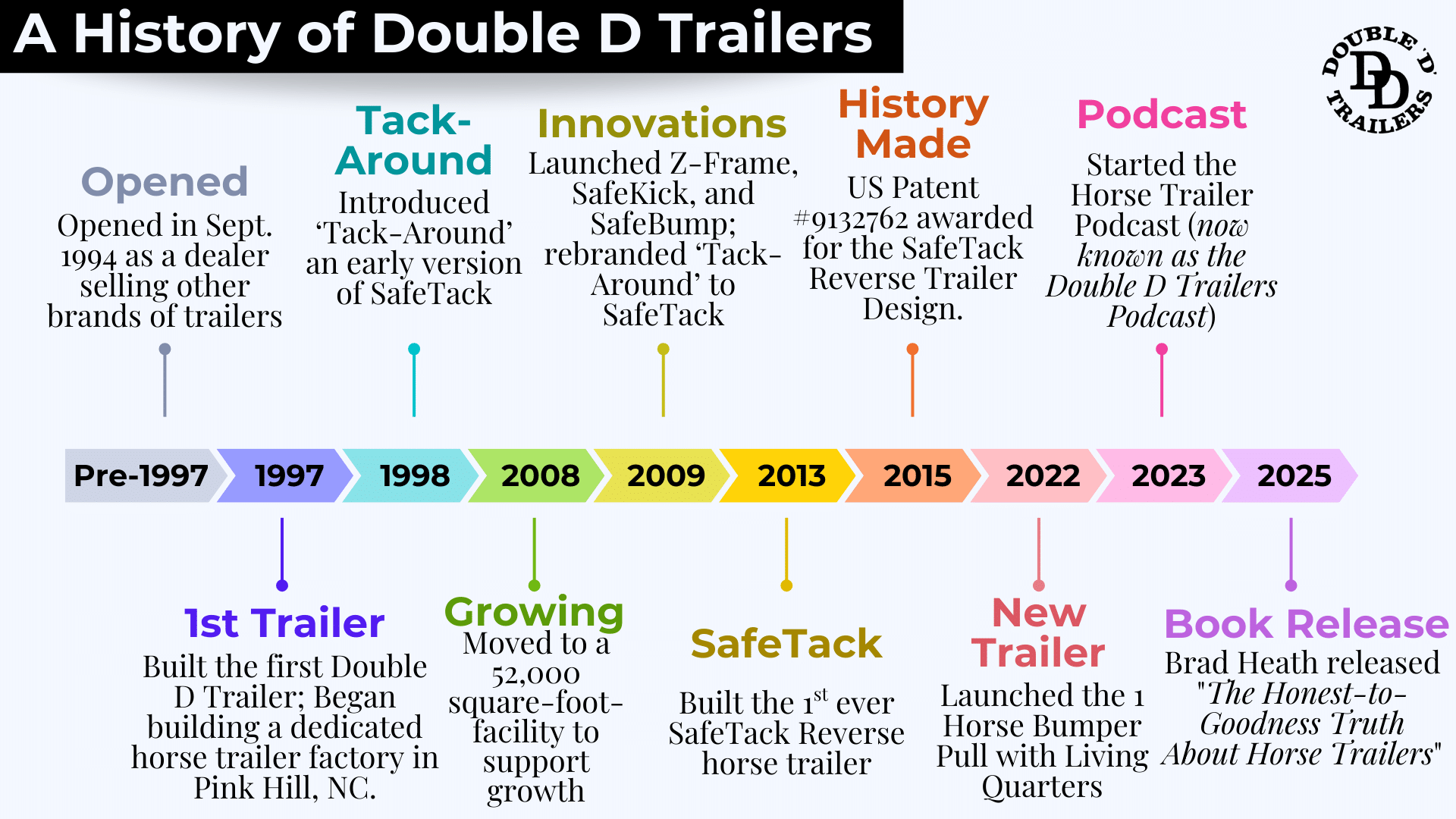

Double D Trailers: A History of Excellence in Horse Trailer Manufacturing Since 1997

Double D Trailers started building horse trailers in 1997 and has since evolved into one of the leading horse trailer manufacturers in the United States. We offer a unique purchasing experience, allowing customers to commission custom horse trailers designed to meet their needs. This model is something you won't find in typical companies in the industry.

Our unique customization process results in more value, safety, and happiness. Because that’s exactly why we own and love horses, right? Horses bring us happiness!'

Double D Trailers Milestones

Our Story: Straight from the Founder, Brad Heath

The Double D Trailers story is best told by the man himself, Brad Heath, founder, owner, and head designer. Through his own perspective, you’ll get to follow the brand’s growth, development, and commitment over three decades, starting with the pre-1997 period when the company was still called Double D Farms.

1994: How We Started as Double D Farms

Back in September 1994, Donald (my dad), Douglas (my uncle), and I (Brad Heath) decided to start a business. Although I was a full-time student at UNC Chapel Hill at the time, I left college to establish what was initially a farm supply retail store, named after our family venture, Double D Farms.

Initially, we sold horse feed, tack, vaccines, and other farm essentials. Gradually, we expanded our offerings and included different brands of horse trailers alongside tractors and hay balers less than a couple of years after we launched the business.

1997: How Double D Trailers Was Founded

It didn’t take long before we realized we had to start thinking about manufacturing our own horse trailers. Nobody really ever wanted any of the trailers we had on the lot. Customers always demanded specific sizes, equipment, color, and certain features. We would order the trailers our customers wanted, but there were huge wait times from manufacturers. Since most of the trailers we were selling were manufactured out West and had to be shipped to our North Carolina location, there were ridiculous freight costs involved, too.

That’s why we thought we could build our trailers and provide customers with a much better level of product and service. More importantly, we could fabricate custom trailers that meet their specs and drastically lower wait times.

When we pitched this idea to First Citizens Bank, they looked at us like we were crazy. We told the bank we wanted to build horse trailers in Pink Hill, NC. Ultimately, they gave us a loan for a new factory, which we built and furnished with all new equipment. Fast-forward to 1997 when our first Double D Trailer was built!

1998: How We Developed the SafeTack Prototype, "Tack-around"

From 1997 through 2007, we only built steel frame trailers with Galvanneal skin. We were very successful with these. They are super safe due to the strong steel frame. Plus, they are sturdy and provide great value to the customer.

However, a pivotal moment came in 1998 when a customer suffered a severe injury while loading her horse. It was a slant load and had a conventional fixed or collapsible rear tack. Her horses were great loaders, so the narrow entryway door beside the rear tack was normally not a problem. This layout is still very common today among many modern manufacturers.

After loading her horse, our customer walked around the outside of the trailer and stuck her arm through the stock side slat to tie her horse. The horse reared up, breaking her arm in the process. It was a horrific injury!

The customer came to us and said, “You need to figure out how to get the <bleep, bleep, bleep> saddle compartment out of the way. It’s dangerous!”

So, we went back to the drawing board and the “Tack-around” – an early version of the SafeTack – was born. Rather than a stationary rear tack compartment, this slant load trailer has a fully enclosed compartment that swings out like a second door. It leaves the entire back of the trailer open for loading and unloading.

As I said earlier, we were building steel frame/Galvanneal skin trailers from 1997 through 2007. These trailers provided great value and safety, but they lacked some of the safety features we see today. For example, they didn’t have an insulated roof to help control the interior temperature for hauling comfort. Not to mention, we needed a frame that wouldn’t rust.

2009: How Double D Trailers Expanded and Developed Safety Trademarks

2009 was a big year for Double D Trailers. We moved to a larger factory because we had outgrown our old facility. We went from a 6,000-square-foot to a 52,000-square-foot building. Around that time, we were eager to make our products stand out from the competition by offering exceptional safety and comfort through features and innovations nobody else could offer.

After more than a year of extensive product development, we launched our lightweight and non-rusting Z-Frame Technology in 2009. It immediately replaced the old steel frame trailers we used to build until that moment. Introducing Z-Frame was a major leap forward because it made our trailers much safer, dependable, and long-lasting, and that was a goal we were eager to achieve.

We also rebranded the “Tack-Around” to SafeTack and developed the new SafeKick Wall System. The SafeBump Roof System, a leak-proof single-piece fiber composite roof, was added to help control the trailer’s interior temperature. 2009 was the year we started using synthetic Rumber flooring a lot more, too - it proved to be the best solution for a safe, non-slip floor surface.

2012: How Double D Trailers Grew a Wider Market With Safety Innovations

We realized that trying to distribute from our original base in North Carolina was going to be a logistical nightmare. So, we moved the entire factory to Wisconsin. It’s more centrally located to service the West Coast, East Coast, and Canada. We’ve been building all our trailers here since January 2012.

Once we started the new product line at the new location (which we still use today) and developed a non-rusting chassis, clients from all over the US began reaching out to us. They liked how our new chassis was stronger and safer than aluminum, but was also lighter than steel.

But that’s not all that has changed in horse trailer manufacturing since we started back in 1997. We used to build a “welded” product, which would rust in the seams over time. Plus, the roof would leak. Since then, a great deal has changed in the industry. Modern sealants, paints, compounds, and primers are much better than they were years ago. Now, we can use technologies like 3M VHB (like 3M tape) to bond materials without welding or mechanical rivets. These innovations allow us to ‘assemble’ a product similar to how they do in automobile manufacturing. We improved other innovations along the way as well.

2013: How We Built the First SafeTack Reverse Slant Load Trailer

In 2013, we had a customer from Texas reach out to us. She loved the SafeTack, but wanted a reverse load trailer. Laughing, I said, “Reverse who?” Long story short, I did some research and learned how reverse load trailers have been around for a long time. But ALL the designs had major safety flaws for the horse and/or the handler. So, we came up with a solution and sent the paperwork for the SafeTack patent to the U.S. Patent Office in May 2013. Later that year, we managed to build the first SafeTack Reverse load trailer.

2015: The SafeTack Design Was Awarded US Patent #9132762

We got the long-awaited patent approval in 2015. By that time, we had already been manufacturing SafeTack trailers for two years. This allowed many clients across the U.S. to enjoy the simple yet brilliant SafeTack design even if it wasn’t patented yet. Here’s how SafeTack made a huge difference:

- Fully enclosed tack compartment with plenty of room for tack and gear

- Completely swings out to the side to create a wide-open entryway

- Makes loading and unloading safer for horses and handlers

Thanks to these advantages and the fact that SafeTack is exclusive to our model lineup, SafeTack Reverse Load horse trailer models account for over 80% of our overall sales.

2022: How the SafeTack Bumper Pull Trailer With Living Quarters Was Launched

The most rewarding part of running Double D Trailers is the ability to provide our customers with products that bring them happiness and fun. Looking forward, we continue to innovate the horse trailer industry with designs like our one-horse bumper pull trailer with living quarters, launched in 2022.

2026 and Beyond: How Double D Trailers Continue To Evolve

We praise the relationships we have with our clients, many of whom have become friends over the years. Their invaluable feedback and recommendations have helped us create the set of competitive advantages we have today. This is why we try to remain engaged with them and the equestrian world altogether in every way we can. Our latest efforts include:

- The Horse Trailer Podcast we launched in 2023

- The Honest-to-Goodness Truth About Horse Trailers book was revealed in February 2026

This is how we keep connected to our industry and contribute to it, but there’s a lot more where that came from. We plan to continue providing resources, innovative solutions, and quality products to our clients. The effort we put into achieving all this is the power that gives us momentum. This approach has worked like a charm for 30 years.

What Drives Us

We continue to pursue the goal we set a long time ago: to offer our clients safe, comfortable, durable, long-lasting, highly customizable horse trailers. What drives us is the variety of processes related to meeting and exceeding this goal. Our team is constantly looking for improvements, innovations, and modern technology to implement in every Double D Trailers design and finished product. This has already resulted in exclusive safety features, durable materials, state-of-the-art fabrication methods, and numerous customization possibilities that our customers benefit from.

Our Commitment

We remain dedicated to enhancing the safety and functionality of our trailers through continuous innovation and customer education.

We’ve written a huge number of informative guides to help educate our customers.

Plus, you are always welcome to contact us directly with questions.