Why You Should Avoid Cheap Horse Trailers

If you’re trying to be frugal and save money, searching for the cheapest option is a great idea, but only when it comes to buying things like groceries, clothes, or toys for your kids. When it comes to buying a horse trailer, you might be tempted to settle for a cheap trailer and save a few bucks - but, don’t be fooled!

If you’re trying to be frugal and save money, searching for the cheapest option is a great idea, but only when it comes to buying things like groceries, clothes, or toys for your kids. When it comes to buying a horse trailer, you might be tempted to settle for a cheap trailer and save a few bucks - but, don’t be fooled!

Buying a cheap horse trailer might seem like a great way to save money now, but it will actually cost you more money in the future. When searching for a new trailer, you get what you pay for - so if you decide to go with a cheap trailer, you’ll end up spending your hard earned money on cheap materials and a “one size fits all” design that’s not the best option for keeping you and your horses safe.

If you want a reliable and safe horse trailer that will last you years and years without giving you any problems, you’ll have to invest in a quality horse trailer that’s designed by experts and built with only the best materials. Trailers like these can be hard to find, and they will cost you more than a cheap horse trailer. At Double D Trailers, we specialize in creating the best trailers on the market. Our trailer designs use the highest quality materials and the most reliable construction to provide our customers with the safest trailer possible.

A Cheap Horse Trailer Will End Up Costing You MORE Down the Road

If you’re still eyeing that cheap horse trailer, just consider how much you’ll end up spending later on. Realistically, add to that cheap trailer price tag the cost of trailer repairs when your trailer starts to rust and break down, veterinary bills when your horses injure themselves on poor design features, and even the cost of a new towing vehicle when your cheap trailer’s uneven weight distribution messes up your truck’s axles.

If you’re still eyeing that cheap horse trailer, just consider how much you’ll end up spending later on. Realistically, add to that cheap trailer price tag the cost of trailer repairs when your trailer starts to rust and break down, veterinary bills when your horses injure themselves on poor design features, and even the cost of a new towing vehicle when your cheap trailer’s uneven weight distribution messes up your truck’s axles.

While you won’t be paying for all those mishaps the day you purchase your cheap horse trailer, year after year you’ll have to shovel out more and more money to deal with all the annoying repairs, preventable veterinary bills, and other trailer mishaps.

But, all those headaches can be avoided by investing in a quality horse trailer that will protect you and your horses, last much longer and drive much better than a cheap horse trailer.

What Are “Fast and Cheap” Horse Trailer Designs?

The truth is, many trailer manufacturers cut corners during the building process. These short-cuts might save you and the trailer manufacturer some money now, but in the long-run, it can end up costing you a pretty penny.

Quite frankly, a lot of trailer companies make “fast and cheap” trailer designs that are built quickly in a factory with cheap materials then sent off to trailer lots to be sold. In an effort to build as many trailers as possible in as little time as possible, they cut corners during the design and construction process.

This might allow them to sell their trailer for less - and catch the gaze of frugal trailer buyers, but this type of trailer construction is a serious red flag. Using low-quality building materials can lead to big issues down the road, and it can put your horse in danger.

All That Glitters is Not Gold - Don’t Be Fooled By Shiny Horse Trailers

Some first-time horse trailer buyers don’t know what to look for when buying a trailer. Often, cheap horse trailers look great on the outside, and even better when you see the price tag. But don’t be fooled. Don’t let the shiny exterior trick you into thinking that the trailer will be a safe and reliable option for you.

Some first-time horse trailer buyers don’t know what to look for when buying a trailer. Often, cheap horse trailers look great on the outside, and even better when you see the price tag. But don’t be fooled. Don’t let the shiny exterior trick you into thinking that the trailer will be a safe and reliable option for you.

Take Katie Schaeffer’s story for example. Katie lives in Goodyear, AZ, where temperatures can stay at over 100 degrees every day from June to September. She knew that with such hot temperatures, her trailer was going to heat up like an oven while traveling in the summer.

Katie had two options - she could go with a cheap horse trailer that used aluminum materials (a metal that heats up super fast on a hot day) and save a few bucks, or she could invest in a Double D Trailer with all the essential safety features.

Katie says, “After reading about aluminum and the heat they transfer I couldn’t possibly put my horse on an aluminum floor of a cheap horse trailer.” She decided to go with a two horse slant load trailer from Double D Trailers. She wanted a trailer company that was truly concerned about the comfort of her horses, and she wanted a trailer that would not just keep her horses safe, but one that would protect her as well.

You see, Katie’s old trailer had a narrow entryway, and it made the loading and unloading process stressful and dangerous. Once, she was even pinned against the trailer wall while unloading her horses! She said, “after being smashed in a trailer getting a horse out, the safe tack and ample room was the final essential factor.” And her new Double D Trailer had all the features she wanted, and was just what she needed.

Katie was glad she decided to invest in a more expensive trailer rather than settle for another cheap trailer - “I know I could’ve spent less, easily. However, you get what you pay for and other companies don’t offer the same safety and comfort features.” Katie has had her Double D Trailer for 4 years now and is so glad she decided to trust Double D Trailers to build her a safe and reliable trailer.

How to Spot a Cheap Horse Trailer

Most cheap horse trailers are set up to look shiny and attractive, but when you take a closer look, you’ll start to notice some serious red flags. When searching for your perfect horse trailer, it’s important to know what important features you should be looking for - and what features to avoid at all costs. Here’s a list of some serious horse trailer red flags that will alert you that the trailer you’re looking at is a cheap horse trailer that’s not worth your time.

Most cheap horse trailers are set up to look shiny and attractive, but when you take a closer look, you’ll start to notice some serious red flags. When searching for your perfect horse trailer, it’s important to know what important features you should be looking for - and what features to avoid at all costs. Here’s a list of some serious horse trailer red flags that will alert you that the trailer you’re looking at is a cheap horse trailer that’s not worth your time.

Feature #1: Cheap and Flimsy Doors

Many horse trailer manufacturers use doors that they bought or imported from another non-trailer company. Some will even just buy a door and bolt it onto the trailer, without considering whether it is safe or not. These pre-fabricated doors are flimsy and bend easily. Most have just a simple door latch that could easily come loose and pop open while you’re driving!

And it’s not just the building material that’s the problem. An inadequate trailer design can also put your horse in danger on the road. We’ve seen trailers that have cheap, flimsy escape doors located right where the horse’s head goes. Any horse could easily kick through a cheap door and damage the trailer, and the horse’s delicate legs.

The Quality Solution from Double D Trailers

All Double D Trailers have sturdy, reinforced doors that your horse won’t be able to bend or kick through. And, the doors always have a double latch system that keeps the door secured in place during travel.

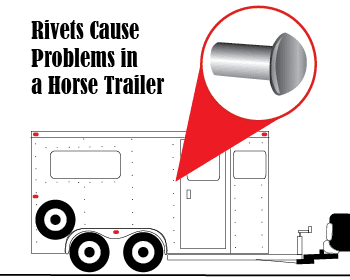

Feature #2: Cheap Metal Rivets All Over the Trailer

Here’s how it typically works… During the manufacturing process, a cheap trailer skin piece is sent down an assembly line. First, the builders stamp out the metal holes, then they quickly secure the rivets using an electric rivet gun. It’s fast and cheap, but here’s why it causes problems later on…

Most trailer buyers don’t notice such a small detail in a trailer. And you might think that these small rivets aren’t a problem. But, using rivets actually does cause problems for your trailer. First, metal rivets create a warped, wavy trailer wall. This is because the metal trailer walls heat up and expand in the sun, and when the rivets are bolted into the walls, they don’t allow the metal room to move and breathe. Instead, the metal walls buckle and warp.

Second, rivets allow for moisture to seep into the metal trailer, which then leads to rust. Although it might seem like the gaps are tiny, they can actually let in a significant amount of water on a rainy day.

And lastly, the metal fasteners create more noise in your trailer. It creates a metal scraping on metal sound that can be annoying to your horse and make him more stressed in the trailer.

The Quality Solution from Double D Trailers

It’s best to avoid cheap metal rivets all together. In Double D Trailers, instead of attaching the trailer skins together with metal screws or rivets, we use a 3M chemical bonding system. Each structural post is cleaned by hand to make sure that it’s completely free of oils. Both sides of the metal sheet are wiped down and cleaned, then we put a strip of tape on the edge and hold it for about 30 seconds to bond the two pieces of metal together.

This is certainly a much longer process than your typical assembly line, but this type of chemical bonding ensures that absolutely no moisture can get into your trailer and cause rust. And, it creates a super strong bond that allows for the metal to expand and shrink depending on the outside temperature.

Feature #3: Cheap Low Aluminum Ceilings

One of the most common things you’ll see in cheap trailers out there is a mill-finished ceiling. These ceilings are basically like unrolling a sheet of tinfoil and putting it on the top of your trailer, then stapling it on to secure it.

There’s 3 huge problems with this type of cheap construction. Number one, it’s very weak. Aluminum is a weak metal that is easily bent, and if your horse rears up in the trailer into an aluminum ceiling, he’s sure to dent your trailer or even bust through the roof.

Number two, aluminum is a super heat conductor. When the hot sun beats down on your aluminum trailer roof, it’ll heat up your trailer interior like an oven, quickly creating dangerous trailer temperatures for your horse.

And number three, since the entire perimeter of the aluminum ceiling is attached with almost 200 screws, it’s very likely that moisture will enter through a leak in one of the screws. This will cause rust and will damage your trailer even faster.

While we’re on the topic of ceilings, it’s also important to avoid trailers with low ceilings. Believe it or not, some trailer manufacturers cut off inches of trailer height to save a few bucks. If you can reach up and touch the ceiling of your trailer, it’s too low.

The Quality Solution from Double D Trailers

Since it’s not aluminum, it doesn’t absorb much heat, and it’s well insulated and painted white to further minimize heat transfer and keep your trailer nice and cool, even on the hottest days.

Double D Trailers are large and spacious as well - all trailers have a standard height of 7’4,” but we can also customize it and add two more inches or even four more inches if you have large breed horses.

Feature #4: Cheap Weak Metal Flooring

Many trailer manufacturers decide to go with cheap metal flooring that requires metal support beams underneath the trailer. This creates a super stiff floor that increases the road vibration your horse feels during travel.

Some cheap trailer manufacturers try to make it sound like this metal flooring is a very stable and sturdy construction. They say things like “our trailers have interlocking metal boards - it’s like having a support beam every 6 inches.” But really, what they’ve done with these “interlocking metal boards floors” is remove the actual support beams to cut down on production time.

Not only does this construction not provide enough support for your horse in the trailer, it also requires an extruding piece of metal on the trailer floor that sticks out into your horse's area. It’s a nuisance for your horse and a tripping hazard for you.

Watch out for Polylast or WERM flooring as well - these are trailer floorings that can be sprayed onto or spread onto a metal floor. They’re made of ground up rubber bits or a combination of chemicals. While they are designed to get rid of the need for a rubber mat in your trailer, these types of floors aren’t the safest option and don’t work well long term. Using this type of flooring is like putting a rug over a rotting floorboard in your house - it just doesn’t fix the problem.

The Quality Solution from Double D Trailers

The safest option for a trailer floor is a Z-Frame chassis that’s built into your trailer design and made out of a zinc and chromate metal fusion that makes it super strong, extremely rust resistant and also minimizes heat transfer.

This flooring material is more expensive, but it provides the perfect combination of strength and cushioning. It protects your horse from busting a leg through the trailer floor, and it’s a softer, more comfortable surface for your horse to travel on.

Other Features To Avoid In Cheap Horse Trailers

When trying to spot a cheap horse trailer - the devil is in the details. Cheap horse trailer manufacturers cut corners during production and that means the little things often get looked over. For example, when you step into a trailer, take a look at the surfaces where the ramp meets the trailer edge or where the doorsill is or where you have to take a step up into a different area.

You’ll likely find that in these areas, there’s trip hazards and uneven surfaces that manufacturers didn’t bother to fix. Don’t pay for a cheap trailer that could cause you to take a nasty fall and send you to the hospital.

Another feature to avoid is horse trailers with black plastic polylining in the trailer interior. Some trailer manufacturers use this material as the primary building material for their trailers. If you walk into a trailer and notice that all the interior walls are covered with this black poly lining, don’t even consider it! This is a weak and cheap material, and it gives your trailer a dark, scary look, making it very uninviting for your horses.

Trailer walls shouldn’t be built out of a flimsy material like plastic. Choose a trailer with a bright white interior - this will make your trailer seem more spacious and your horses will feel much more comfortable loading into the trailer.

It’s also important to take a look at the horse trailer butt bars. Even some of the more well-known and professional trailer brands sometimes lack essential safety releases on the butt bars. When trailers don’t have these safety releases, it can put your horse in a dangerous situation if he gets a leg over the butt bar and gets stuck.

Make sure your trailer has safety releases on the butt bars and chest bars, and make sure they work even when your horse’s full weight is on them. This can save your horse from getting seriously injured if he gets stuck in an awkward situation in the trailer (as you know horses are prone to do).

Another safety hazard that’s common in cheap trailers is open wheel wells. Some horse trailer companies that don’t take the time to cover up and block out the wheel wells. This is a real safety hazard because your horse could easily accidently step into the wheel well and injure or even break his hoof or leg.

What Makes Double D Trailers So Much Better?

By pointing out so many red flags and dangerous features in our competitor’s trailers, it could seem like we are trash talking cheap horse trailer manufacturers. But, that’s not why we’re telling you all this. In all honesty, we believe that when it comes to choosing a horse trailer, your safety and your horse’s safety should come first.

After years and years in the equine business, we’ve seen firsthand and heard stories of terrible horse trailer accidents. From seeing a horse flip over in the back of a trailer to hearing about handlers getting slammed into trailer walls during loading, we know firsthand the dangers that can come with trailer travel. But, these accidents are preventable!

With a quality trailer that has all the essential safety features, you can travel safely and confidently and avoid dangerous situations. But, cheap horse trailers simply aren’t built with your safety in mind. And many first-time trailer buyers might see a beautiful trailer with a super affordable price tag and think they’ve found the perfect trailer. Unknowingly, they are putting themselves and their horses in danger.

What Double D Trailers Customers Have to Say About Their Trailers

Many of our customers have had cheap trailers in the past. After dealing with all the headaches and problems their cheap horse trailers have caused, many of them decided it was time to invest in a quality horse trailer. When they make the switch to Double D Trailers, the difference is astounding. Just take a look at what a couple of our happy customers have to say….

Tom from Florida has three horses and a pony. He and his wife are retired and love to go on vacation with their horses all over the country. When their old trailer wore out, Tom and his wife decided to go with a 3 Horse SafeTack Bumper Pull Trailer.

And when Tom’s trailer arrived at his ranch in Florida, he was thrilled. He said, “my horses love the special features my Double “D” Trailer has that aren’t available on any other trailers I’ve seen. The rumber flooring is a special option that my horses love, and it’s super easy to keep clean. I don’t think any other company offers that.”

Mike, a firefighter from South Carolina, had an aluminum trailer before he switched to his new Double D Safetack Reverse Living Quarters Trailer. What inspired him to make the switch? Well, during a 3-day animal rescue class Mike learned just how dangerous aluminum trailers are. He decided he wanted to do all he could to keep his horses safe during travel. So, he got rid of his old aluminum trailer and bought a Double D Trailer.

Mike says one of the things he loves most about his new trailer is the one-piece roof. He says his new trailer is so much cooler than his old trailer - “even sitting out in the 100-degree Carolina sun, the interior stays much more comfortable compared to our previous metal roofed trailer.”

Designing his new trailer was straightforward, easy, and fun. And the best part was that Mike got everything he wanted. He said “The best part was being able to ask for EXACTLY what we wanted! An extra 50-gallon water tank underneath? No problem. A fender light to show braking and turn signals are working? No problem. Can we put a shelf here? No problem. Can we add a cabinet door here? No problem. The service and communication were better than what we experienced with a brick and mortar dealership.”

And Mike’s two horses - a Bashkir Curly and a Paso Fino - love the trailer as well. But the best part is that Mike knows now that when he hits the road to head out for a trail ride, his horses are safe and sound in his Double D Trailer.

You can check out what other Double D Trailers customers have to say about their new trailers here, or reach out directly to Brad Heath to ask any questions you might have.

Frequently Asked Questions

What is the average price of a horse trailer?

Horse trailers can cost anywhere from $5,000 to $100,000 or more, depending on the make and model of the trailer. Typically, bumper pull horse trailers are less expensive, ranging from $10,000 to $30,000. Gooseneck horse trailers are more expensive and can cost anywhere from $35,000 to over $100,000. Adding living quarters to your horse trailer can also increase the price of your trailer.

Are horse trailers cheap?

While there are cheap horse trailers for sale at horse trailer lots and live equine events, these horse trailers lack many essential safety features and can put you and your horse in danger. Typically, horse trailers are not cheap, and will cost anywhere between $5,000 to over $100,000. Since buying a horse trailer is such a big investment, it’s important to make sure you go with a reliable horse trailer manufacturer, rather than settle for a cheaper alternative.

What are the most popular trailer designs?

The three most popular types of trailers are bumper pull trailers, gooseneck trailers, and horse trailers with living quarters. Slant load horse trailers are some of the most popular horse trailer designs. The slant load design can be for both a gooseneck horse trailer or a bumper pull horse trailer. Straight load horse trailers are also popular.

What is a good horse trailer to start with for a first time buyer?

Most first time horse buyers start with a bumper pull horse trailer because they are smaller and lighter and can be pulled by different types of tow vehicles. However, the trailer that’s best for you will depend on how many horses you have, how big they are, how often you plan to use your trailer, and whether or not you want to add a living quarters area to your trailer. Whether you decide to go with a bumper pull trailer or a gooseneck trailer, you can customize it to make it just what you need at Double D Trailers.

Why should you avoid cheap horse trailer companies?

Horse trailer manufacturers that make cheap horse trailers focus on making the trailer as quickly and as economically as possible. This means that they often take shortcuts in the design and construction process and use cheap, unreliable materials. This creates a cheaper final product, but also means the trailer lacks essential safety features and is more likely to cause problems and need repairs down the road.