Understanding Horse Trailer Tires, Axles and Weights (Part 2 on Lawsuit)

Recently, a customer reached out to Double D Trailers on advice for designing a new trailer, and for direction involving an ongoing lawsuit she has against another trailer manufacturer. (this is part 2 of the Article. Part one was sent earlier)

CUSTOMER EMAIL:

Hi! I really appreciate you helping me with this. The tires are new I blew them 1 by 1 after 6 months of owning it. I’ve only had it for 2 years. So if I’m not “over loaded” what happen to the tires axles and bearings and why is theaxle straight across not bowed?

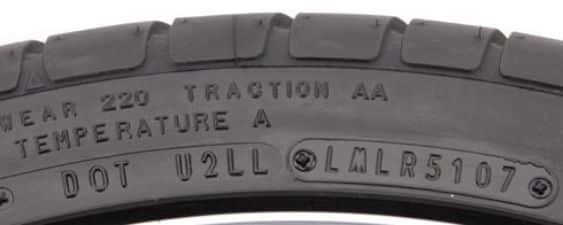

In the Date Code LMLR5107

51 Indicates the 51st week of the year

07 Indicates the tire was made in 2007

DOUBLE D TRAILERS RESPONSE:

I am not sure that you aren’t overloaded, but my guess is more than likely you aren’t but are very close to capacity. I agree that a heavier tire would be nice, perhaps a “D” rated rather than the “C” rated. Unfortunately, we see tire failures pretty common in the industry. Most of the time what happens Is as the trailer sits for a period of time (weeks/etc.), the tires will lose some air pressure. When that happens and the tire Is operated, heat will build up and it breaks down the rubber compound, weakening the side walls. Particularly when you are running a tire at close to loaded capacity it compounds the issue. Even if the tire didn’t blow out the first time and you add air at a later date, the damage has already been done to the tire so it’s a matter of tire before “CABOOM” and it fails. Of course you could have hit road debris as well, that happens too. The other issues we see with tires are the age of the tires. Customers “think” as long as the tread looks good, the tire is good. Sunlight, Air, Rain, Heat, Cold all affect rubber in a negative way so the day a tire is made it begins aging (sort of like us humans). The life of a tire is dependent upon use, heat cycles (it gets hold/cold during use), and exposure to the elements. Generally, it is recommended to replace tires every 3 to 5 years which means…..absolutely, that tires will fail on horse trailers in as little as 3 years if not replaced. You can always look at the Date code on the tire to see the true age based on the information of the image of the tire above.

Generally, if tires are aired properly before each use, AND changed every 3-5 years, we see relatively low failure rates.

In regards to your question about bearings, bearings do fail. I would be interested in knowing the year of this trailer and age of the axles as it looked from the photo to be much older than two years old. Bearings are no different than tires, they go through heat cycles but as long as they are repacked and greased/serviced properly, it is uncommon to see failures. I believe you mentioned your brakes were fried, which is probably what “cooked” the bearing. If the brake control was turned up on your tow vehicle so that the brakes were doing a lot of extra work, it could have easily heated the bearing and boiled the grease to the point to cause a premature failure. Heat is what causes a bearing to fail, typically not weight. Obviously being overweight would cause more heat, but if an axle is rated by the axle builder to haul 7,000 lbs, in reality it will haul a bit more than the stated capacity. Regarding your brakes/bearings, I would recommend to check your wiring to make sure you didn’t have a small charge actuating the brakes while driving, or either the brakes were set too tight causing undo heat in the bearing resulting in failure of the bearing, and brake system.

Lastly, on the axle bend…..believe me, I am no engineer. But my experience has been the “bend” is there when unloaded, and typically goes straight as the load is applied. As long as the axle isn’t bent down, or you are seeing significant uneven tire wear the bend is probably functioning as it should be functioning.

CUSTOMER EMAIL:

And isn’t bad to be driving all the time with the load that close in weight?

DOUBLE D TRAILERS RESPONSE:

Remember, heat is the culprit to tires/bearings/and brakes. The greater the load, possibility of more heat. As long as the load isn’t in excess of the capacity, and the tires/brakes/bearings are serviced properly in my opinion being at or under is acceptable. When hauling only one horse you would have been well under, and two horses close to capacity.

CUSTOMER EMAIL:

I know its hard to answer these questions without actually seeing the trailer. But I really don’t want to make another mistake. I researched everything before I bought a trailer but I forgot the axles.( won’t do that again) And maybe you could tell me if I would be able to get larger axles on the trailer I’m looking at through your company?

DOUBLE D TRAILERS RESPONSE:

On trailers I build, I do not have problems with matching the axle and tire to the weight being hauled. Having too little suspension can create problems, and having too much can be just as bad. I would think the ride on your trailer is very smooth….I would probably change the tires to a “D” rated rather than “C” rated and make sure you keep the pressures proper before each use. I would also get the tongue weight so you can calculate exactly how much weight your tires/axles are carrying to determine if the suspension is sufficient.

True story: Sometime ago, I built a 2 Horse Gooseneck Trailer for a customer. We ended up adding 1′ to the horse stall, and extra footage to the dressing room. We also added a small living quarter package to the trailer. I don’t remember the exact specs but the overall weight ended up being around 5,500 lbs. She stated her horses weighed 1,500 lbs each plus she was hauling a LOT of hay inside the front dress for a total of 8,500 lbs. Based on a 25% tongue weight and a 7,000 lb axle (same as yours) she could haul about 9,300 lbs including the weight of her trailer, at 8,500 she would be under. My recommendation was a “D” rated tire, and a 3,500 lb capacity axle. She was adamant about having a heavier axle and insisted with the size of her horses and load she needed a heavier suspension. This was my exact email to her: “upgrading to a heavier suspension when especially when hauling only one horse will transfer too much shock, noise and vibration back to your horses feet and legs and could cause problems during hauling, I recommend against it”

The short version, against my advice she paid to have a larger axle installed under her trailer with capacity of 10,400 lbs and stayed with my “D” rated tire recommendation. After receiving her new trailer, 3 months later she called terrified that while hauling a single 1,000 lb horse in the rear stall, her horse attempted to jump through the drop down window while traveling. He was bouncing all over the place….suspension was too stiff. I ended up, at my expense, paying to replace the axles with 3,500 lb capacity as we had originally suggested and took back the heavier suspension. I also repaired a window and trim inside her trailer from where the horse damaged when he tried to exit. After making the change, she said the difference in towing was “night and day”. Of course hauling a single 1,000 lb horse was a long ways from the 3,000 lbs worth of horses she originally said she would be hauling, plus hay. It’s difficult to say what caused her horse to “spook” and if indeed the suspension was a contributing factor but there haven’t been any issues since that time.

Having a suspension that is properly matched to the weight being hauled is the best, not severely under/or over rated in my opinion.

(NOTE: If you missed the first part of this article, click here)

If you find this information helpful, please “share” with your friends using the social sharing features.