A Buyer's Guide to Horse Trailer Materials and Parts

Materials and build quality define a horse trailer’s safety, and some horse owners learn this the hard way. For horse owners like Amy Chenard, this realization dawned not in a calm reflective moment, but in the turbulent aftermath of an accident. In March 2023, while on the road, Amy experienced every horse owner's worst nightmare: a high-speed collision that sent her truck and horse trailer careening into a ditch. You might wonder what this story has to do with horse trailer materials. The answer is simple: everything. The quality of the materials and the craftsmanship implemented in the trailer saved the lives of Amy’s horses.

Choosing the right materials and parts is crucial not only for a horse trailer’s safety but also for its lifespan, comfort, reliability, and other aspects. Recognizing the vital role played by the trailer's build in protecting Amy’s beloved animals, she didn't hesitate to opt for another unit from Double D Trailers.

This comprehensive guide delves into the various materials used for building horse trailers and their key components, such as frames, floors, walls, roof, insulation, dividers, windows, horse stalls, living quarters areas, chassis, wheels, and so forth, emphasizing their benefits and distinct characteristics.

Why Does Knowing Your Horse Trailer Materials Matter a Lot?

Knowing the materials used in your horse trailer is crucial because they directly impact the trailer's rigidity, lifespan, and maintenance costs. This knowledge is invaluable for horse owners, enthusiasts, professional equestrians, racing teams, veterinarians, transportation and rental companies, and many others.

When you know the dos and don’ts in horse trailer manufacturing and the differences between every material typically used for fabricating core parts and areas of the trailer, you are prepared to make an informed buying choice. This decision is based on a combination of your newly gained industry-specific knowledge and your personal needs and preferences.

Understanding the Basics of Horse Trailer Construction

Before the actual construction of a horse trailer begins, the selected materials significantly influence its performance and quality. In the design, research, and development phases, manufacturers decide on the combination of materials and resources to bring their blueprint to life. The trailer's practicality, safety, weight, and capabilities are determined during this time. This foundational stage dictates the rest of the production process. If designed with safety and functionality in mind and fabricated in compliance with all strict industry standards, a horse trailer is bound to incorporate top-notch materials and features.

Horse Trailer Materials and Key Components During Construction

To truly grasp the significance of selecting the right horse trailer materials, we must journey through the fabrication process. Let’s explore how top-notch horse trailers are crafted.

Frame Construction and Materials

A horse trailer’s frame is the one key component that defines the rig’s performance, load capacity, longevity, and flexibility. The perfect horse trailer frame is solid but lightweight, and it’s well protected against corrosion and the elements. Not only do rust-resistant frames extend a trailer's lifespan, but they also simplify maintenance and enhance resale value.

Available chassis materials in the market

The times when horse trailers were mostly made using bare sheet metal and welded iron bars with zero rust protection are long gone, at least for most manufacturers. When aluminum was introduced to the industry in the 1980s, it was a game changer, but it didn’t really solve all manufacturing problems related to frame or skin construction. Today, there are several chassis material types and combinations to choose from, and some of them are significantly better than others.

Selecting the chassis material

A horse trailer’s chassis can be either made using steel alloy, aluminum, or processed steel.

- Steel Frames: Crafted using interconnected steel tubes, this chassis type is usually strong and capable of carrying heavy loads.

- Aluminum Frames: These frames offer the advantage of weight reduction, leading to an overall lighter horse trailer. However, they are much more expensive, and less flexible than trailers with steel frames, which affects safety and handling. Aluminum tends to crack instead of flex.

- Composite Structures: This category houses some of the best innovations in horse trailer frame construction. Double D Trailer’s Z-Frame technology is the best example. It uses a zinc-chromate coating to create a structure that’s five times stronger than common steel frames, and it’s completely rust-proof, too. Plus, this process doesn’t add much to the final trailer price, neither does it affect the rig’s weight.

Overall, a Z-Frame horse trailer chassis is stronger, more flexible, and cheaper than a similarly sized all-aluminum one, not to mention its better load capacity and weather resistance. It’s a smart choice that ensures safety, a longer lifespan, and towing agility.

Wheel and Axle Installation and Materials

A horse trailer’s axles, wheels, and tires absorb plenty of stress, meaning that there shouldn’t be any compromises related to the materials used for manufacturing them. When in use, the running gear of the trailer is exposed to the road surface and the elements, generating a lot of friction and heat while trying to cope with the weight above and the forces of gravity at the same time.

Available wheel and axle materials in the market

Horse trailer wheels can be made from steel or aluminum (cast or forged). Their size and width also matter, but choosing cast aluminum wheels is a good decision: these wheels are typically durable enough to withstand high loads and potholes (when calculated right according to the trailer model), and they are also lighter than steel wheels, thus reducing the overall weight of the trailer. As for trailer tires, they need to be compliant with the trailer’s weight, speed, number of axles, and suspension design and settings. Some horse trailers require tires with extra (sometimes reinforced) sidewall or thread width.

Horse trailer axles are primarily made of steel but often feature miscellaneous smaller components such as bearings and suspension connection elements fabricated from various alloy materials. Some trailers feature leaf spring suspension to which the axles are attached. Having steel axles mounted on torsion bars produced from heat-treated steel is the best configuration in terms of road stability and smooth ride.

Assessing strength, balance, and potential load

The most important aspect of a horse trailer’s wheels, tires, axles, and suspension is for these components to be corresponding to the trailer’s weight, carrying capacity, and purpose. They must enhance the trailer’s weight/load balance, comfort when empty or fully loaded, and road stability. It’s all a matter of calculation: the running gear setup should be exactly the one that fits your trailer and its load. Understanding GVW and GAW (Gross Vehicle Weight and Gross Axle Weight) is key here. The former stands for the combined weight of your trailer and its load, and the latter represents the load each of the axles must be capable of carrying. These metrics guide the selection of optimal suspension, wheels, and tires for any given trailer. Equipping a trailer with an ill-fitted axle or suspension system, whether too weak or excessively robust, can be detrimental.

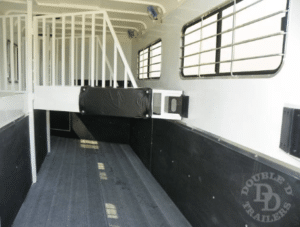

Floor Installation and Materials

Horse trailer flooring is a rather underestimated component that actually matters a lot. It’s crucial for the safety of the horses inside because it should prevent slipping and enhance the loading and unloading processes. Proper horse trailer floor materials also protect the trailer’s structure from horse urine, debris, and other contaminants, not to mention that it can reduce road noise and vibration, thus increasing ride comfort.

Available flooring options in the market

Depending on the maker, class, and type, a horse trailer may be equipped with several floor materials, as follows:

- Aluminum Floors: At first glance, aluminum floors inside a horse trailer may seem like a great solution, but it’s not the best one. Aluminum tends to bend or crack easily, so a floor made entirely using this metal will quickly become deformed and uneven. Aluminum also corrodes, which weakens it eventually. Also, this material is an excellent heat conductor, which is a negative aspect when it comes to using it for horse trailer floors, walls, and roofs.

- Wooden Floors: Wooden horse trailer floors are a better option than aluminum. They reduce heat transfer drastically and absorb noise, but the best part is that horses have a lot more grip when traveling on wooden floors. Plus, wood is cheaper to use for this purpose.

- Composite Flooring: These emerge as the top contenders for horse trailer flooring. Precisely cut and secured floor mats allow for extra traction for horses’ hooves and provide the ultimate noise and vibration reduction. These materials can reduce heat transfer by over 70% compared to all-aluminum flooring.

Choosing the proper flooring material

The best horse trailer flooring material is safe, long-lasting, rust-proof, easy to maintain, and affordable. It also contributes to the trailer’s ride comfort and overall safety by providing better insulation and grip and reducing heat transfer. Innovative materials such as the composite Rumber flooring type have already proven to be the ultimate choice.

Wall and Roof Construction and Materials

Other than the floor, the walls and roof of a horse trailer are the only components protecting your horses from the outside environment. Therefore, the materials used to produce them are crucial for the horses’ safety and comfort. These materials need to be strong enough to withstand accidents and the elements, but they should also be as light as possible to keep the center of gravity and the overall trailer weight low. Proper insulation is also a must-have perk. As for installation materials, special chemical bonding solutions such as 3M’s VHB system have become a preferred option for some horse trailer makers, Double D Trailers included. As shown in 3M's VHB vs rivets video demo using a bowling ball, these bonding systems make rivets and bolts obsolete (which several other manufacturers still use to secure the outer skin of the trailer to its upright structure), thus reducing the number of weak points on the trailer. Plus, they provide more strength compared to traditional welding.

Available wall and roof systems in the market

Two prevalent materials in the construction of horse trailer walls and roofs are aluminum and composites. Aluminum can be easily bent and when you add the fact that it’s a heat conductor, it becomes apparent that it’s not the best choice, although it has aesthetical qualities. Composites, on the other hand, are a much better choice: they are light, agile, don’t conduct heat, provide great insulation, and enhance good accident safety.

Several technological advancements have allowed groundbreaking materials to be used in horse trailer manufacturing for the first time. Double D Trailers has developed SafeTack Reverse Carbon: the first 3D-printed horse trailer in the world. It utilizes innovative materials such as carbon fiber to create a stronger-than-steel structure that’s lighter than all-aluminum alternatives and provides super longevity combined with exceptionally low maintenance and extremely short turnaround times.

Understanding interior skin materials and safe wall systems

Horses can get hurt while inside the trailer in case they experience some kind of stress or panic and rear up. This may lead to head-to-head injury if the roof and walls material cannot provide protection in such cases. Therefore, the interior walls and roof must be sturdy enough to withstand a horse kick instead of breaking to bits or tearing up. The same goes for traffic accidents: remember that the walls of your trailer are the only barrier standing between your horses and everything else during hauling.

Double D Trailer’s SafeBump fiber composite roof technology is a prime example of how a horse trailer roof should be designed. This roof system uses fiberglass as a way to increase the comfort and safety of your horses in the scorching heat or the freezing cold while reducing the trailer’s weight and maintenance costs. Composites do not corrode and can last way longer than aluminum components if maintained properly.

As for the walls, even double-layer aluminum walls would not be as strong, easy to maintain, and affordable as the better option: Galvalite walls with additional insulation. Galvalite steel is cheaper, rust-proof, and provides the kind of structural strength you need for your horses. Some horse trailer manufacturers offer composite walls mounted on a steel structure, which is another good solution, but it always comes at a hefty price.

Controlling temperature with proper roof material

The comfort of your horses during transportation requires insulated and padded walls, adequate ventilation, and enough room for movement. Choosing a material with low heat conducting qualities and adding proper insulation will allow your horses to enjoy a tolerable stall temperature. When combined with enough fresh air provided by the ventilation system of the trailer, their comfort should be guaranteed. The ultimate choice is the low-weight, heat-insulating (and painted white) SafeBump system.

Partitions and Dividers Installation and Materials

Head dividers, chest and butt bars, and all other components of a horse trailer’s stall interior are next in the list of key areas where choosing the right material is crucial. These bits need to be designed flawlessly to prevent injuries during transportation or in case of a road accident, for example.

Some dividers are not as solid as they should be: they feature gaps that a horse’s leg or head could easily get stuck into, thus leading to injuries. Sometimes, head dividers are almost completely solid, resulting in a confined horse stall, and that causes stress: horses don’t like solitary confinement at all, and nobody wants a nervous horse during hauling. Therefore, tubular head dividers work best because they allow for optimized airflow and more light. Still, even the most brilliant design would not prevent failure if either of them is made from the wrong materials.

Available options in the market

All dividers and bars inside the horse area need to be made from proper materials such as steel alloy or, better yet, processed steel (the Z-Frame technology comes in handy here). Aluminum bars are lighter but can succumb to the horses’ weight upon impact and cause injuries. Last, but not least: securing the dividers matters a lot, meaning that flimsy latches will never work. They should also be made from the same material as the divider itself, allowing for securing the latter the right way.

Providing comfortable horse areas

While the overarching theme in horse trailer construction emphasizes safety, it's pivotal to reiterate its importance. There are plenty of horse area features that enhance comfort, and their quality also depends on the materials they comprise. Interior wall padding is the most important of them all: it needs to be thick enough to handle horses’ weight in case the latter comes in contact with the wall, and it should also be easy to clean and maintain.

Door and Window Installation

For horse trailers, the strategic placement of doors and windows is just as critical as the quality of the materials used to craft them. The latter determines the quality and longevity of these components: since they’re moving parts that are constantly opened, closed, or swung in and out (depending on hinge design), they need to be tough.

Available materials in the market

Horse trailer windows mostly comprise aluminum for the frame and bars, rubber for the seals, and acrylic, polycarbonate, or safety glass. As for doors and ramps, the material used for them is mostly aluminum or composite, depending on their placement and the materials used for fabricating the trailer itself. The best horse trailer makers today appoint specialized companies to produce windows for them instead of designing them on their own, as it’s the kind of job that requires nothing but the correct equipment, knowledge, materials, and experience.

Selecting materials for a sturdy and safe structure

The materials used for doors and windows listed above are important, but, as already mentioned, the safe structure of a window is also the result of a design. Windows featuring mid-mounted latches, drop-down screens, and separate bars enhance practicality and increase safety by a lot, making them the best choice.

Double D Trailers windows are different than other horse trailer manufacturers: Using a mid-latch easy-to-reach drop down window system. These windows have separate bars and a drop-down window screen.

Interior Finishing

In determining a horse trailer's overall quality, the interior finishes and their materials play a critical role. It's essential to closely examine these details when considering a trailer purchase. Both the horse area and living quarters deserve equal attention.

Essential components of the horse area

- Dividers and Bars: Typically made from processed steel.

- Floor Mats: Commonly crafted from rubber or composites.

- Lighting: Generally made from metal or plastic.

- Ventilation: Often composed of aluminum.

- Doors and Windows: Materials range from aluminum, rubber, acrylic, to polycarbonate and glass.

- Padding and Bedding: Often constructed from foam, vinyl, cardboard, and composites.

- Hay Rack: Usually metallic.

Choosing the right materials for the horse area

We already covered some of the essential horse area components and the importance of the materials they’re made of. However, we can’t stress enough how important it is to combine the correct materials for every last detail. They need to be easy to maintain and replace, depending on the component, and they should not add a fortune to the final price. Choosing the best materials doesn’t only enhance practicality and safety, but also brings more value and often extends the lifespan of the horse trailer. When you learn all about different materials’ qualities, you will know what to look for and what to pass on.

Essential living quarters and storage features

The living quarters and storage area of any horse trailer more or less determine its usability. They can either add to the trailer’s value or reduce it if not done properly. Again, good planning and practical design should meet quality materials for a great result.

A horse trailer’s living quarters should comprise a plethora of high-grade materials, as follows:

- Hardwood: Preferred for floors, cabinets, and furniture.

- Leather and Fabrics: Used for carpets, upholstery, wall padding, drapes, and sheets.

- Metal Alloys: Primarily aluminum and steel for fixtures and appliances.

- Plastic and Composites: Common for switches, bathroom equipment, and handles.

- Rubber: Ideal for seals, insulation, and floor mats.

Choosing the right materials for the living quarters

In the living quarters, where comfort is paramount, material selection is everything. By comparing different material options for every part of the LQ area, you can determine which combinations of materials and resources work best.

Prioritizing functionalities in lighting materials

Horses despise dark and confined spaces and can suffer from a condition called pleuropneumonia, also known as travel sickness. One way to help them deal with long trips is to ensure the horse area is well lit. This is often impossible without artificial light, therefore, proper lighting is required. Having strategically placed and reliable light fixtures is a must. To avoid any issues caused by electrical malfunctions and to ensure ease of maintenance, all lights inside the trailer must be quality-made units supplied by trusted companies – which is the route most horse trailer makers follow.

Exterior Finishing

The exterior of a horse trailer is about more than just good looks, shiny paint, and attractive vinyl decorations. Since it’s constantly exposed to the elements, a horse trailer’s exterior needs to withstand harsh weather, meaning that it should be rust-resistant and its finish should also last many years when cared for accordingly.

Common exterior finishings

Building a horse trailer is a complicated process that consists of hundreds of carefully planned steps. When most of the fabrication work has been done, the time for applying the exterior finish comes. This stage involves several stages, as follows:

- Primer Application: An epoxy primer is sprayed onto the frame to prolong its life.

- Interior Painting: Interior spaces and fixtures generally receive a coat of paint, often in white.

- Wall Sheet Attachment: Wall sheets are fixed using rivets or advanced chemical bonding systems.

- Roof and Window Installation: The roof system and windows are securely fitted.

- Chassis Painting: The chassis gets its final color.

- Adding Aesthetic Touches: Once the paint dries, badges, decals, and graphics embellish the trailer.

- Final Assembly: The trailer is finalized with the installation of lights, fenders, spare wheel, running boards, hay racks, fasteners, ties, and other accessories.

Double D Trailers are completely customizable - any exterior finishing can be tailored to be exactly that way you want.

Personalizing your trailer

While the standard finishing process adheres to a specific sequence using predefined materials, the beauty of customization emerges when one prioritizes superior materials tailored to individual needs. This personal touch is what sets custom-built horse trailers apart. The value of personalizing your horse trailer, especially with the best materials, is priceless. Manufacturers like Double D Trailers allow their clients to become part of the fabrication process. This collaboration ensures that clients not only get maximum value for their money but also a trailer that aligns perfectly with their vision. While certain components of the trailer might remain standardized, a custom-built model stands distinctively apart from its off-the-shelf counterparts.

Inspection and Quality Control: How to Conduct Your Own Quality Control Before Buying a Horse Trailer

Performing quality control is what all horse trailer makers do before they roll out yet another finished trailer. These checks, however, are based on the manufacturer's standards, which can vary. Yet, as a prospective buyer, your understanding of horse trailer materials can be used to inspect the trailer meticulously —be it brand new or pre-owned. Here are four easy steps:

- Start with determining the materials used for all crucial parts: chassis, axles, hitch, walls, roof, stall dividers, doors, ramps, and so forth.

- Inspect how different components are pieced together and check for gaps, leaks, and other weak spots.

- Make sure all latches, bars, ties, and fasteners are solid.

- Assess the interior temperature and airflow if you get the chance.

These and other similar steps will help you dodge a bullet. By engaging in quality control, you will easily find the top-quality trailer you’ve been looking for.

How Do Materials Impact Horse Trailer Parts?

Choosing the right materials for a horse trailer is crucial for ensuring safety, durability, and long-lasting performance. A component made from subpar materials can result in plenty of headaches, dangerous situations, extensive maintenance, or reduced lifespan. Armed with the insights from this guide, you'll be better equipped to differentiate between a genuinely well-constructed trailer and one that's merely superficial in its quality.

What are the basic components of a horse trailer?

A horse trailer comprises dozens of basic components, all of which can play a key role in the aspects described above. The most common components to pay attention to are as follows:

- Dressing Room: Positioned at the front of the horse area, these rooms are typically small and primarily intended for outfit changes during events.

- Escape Door: A vital safety feature, these doors provide an alternative exit for the horse or handler in emergencies, other than the main loading door or ramp.

- Horse Compartment: This is the primary space designated for transporting horses, equipped with stall dividers, butt and chest bars, tie rings, and more.

- Horse Stalls: These sections within the horse area are tailored for individual horses. Depending on the trailer, there may be between two to four stalls.

- Long and Short Walls: In slant load trailers, these walls demarcate the dressing room. They comprise the shortest wall and its opposite counterpart.

- Head Dividers: Designed to separate horses within the compartment, these dividers often feature a tubular structure to maximize air and light.

- Gooseneck: Specifically found on gooseneck trailers, this hitch connects the trailer to a coupling mounted in a truck’s bed.

- Weight Distribution Hitch: A system that utilizes spring bars to evenly distribute the trailer's weight, enhancing towing stability and comfort.

- Cowboy Shower: Essentially a portable shower, often set up in the horse area. Its design can cater to both cold and hot water requirements.

- Roof Vents: Enhancing interior ventilation, these systems refresh the air, making the compartment more comfortable for the horses.

- Ramp or Step-up Entry: Horses either ascend a ramp or step directly into the trailer, defining these two types of entries.

- Tail Curtains or Rear Doors: Usually accompanying rear loading ramps, these features provide additional safety. They're sometimes detachable for increased airflow during warmer months.

- Tack Room: Specifically for storing horse tack and equipment separately from the horses. Some advanced designs may include wall organizers for added convenience.

- Padding: Often made of foam encased in vinyl, this protective layer on the walls minimizes potential injuries during loading, transportation, or unloading.

- Tie Rings: These metal loops secure the horse during transport and when the trailer is parked. Some ties include a quick-release feature for emergencies.

The Impact of Materials on Horse Trailer Parts

All the trailer parts listed above can suffer from poor materials that affect their build quality. If this is allowed, the result is always an endless string of issues, heavy maintenance, and overall disappointment, not to mention that failure in some of these components can cause injuries or accidents.

For example, a gooseneck hitch needs to be of exceptional quality to ensure a reliable connection with the towing vehicle’s coupling mechanism. A single flaw in this horse trailer component can be disastrous.

Here’s another example: door latch mechanisms. What appears as a small detail could result in a lot of trouble. If a door latch fails, this could lead to compromised safety and to possible accidents.

The overarching lesson here is clear: never compromise on your horse trailer's material quality. Though top-tier materials may come with a higher upfront cost, the security and peace of mind they provide are priceless.

What Factors Determine the Best Horse Trailer for Ensuring Equine Safety?

The factors that determine the best horse trailer in terms of equine safety include durability and weight. The ultimate equine safety can only be guaranteed by horse trailer manufacturers with a proven track record of recognizing these and other important aspects.

Durability

A horse trailer’s durability is determined by its design, safety features, and the combination of materials it boasts. The most durable models available today comprise advanced technology and innovative structures. A couple of examples are the patented Z-Frame technology that utilizes a special coating to make steel five times stronger, and the use of rumber flooring, which is made of synthetic material from recycled tire bits.

Weight

To guarantee the safety of the horses it transports, a horse trailer needs to be light and have a low center of gravity. This improves handling and makes towing easier and more predictable. Plus, it allows for better load capacity by keeping the curb weight of the rig lower than usual.

Cost

Although not directly related to horse safety, the cost of a horse trailer can give you а general idea of its safety, based on what features and perks it offers and how all other comparable trailers are priced. Manufacturing a safe, rigid, full-fledged horse trailer requires expertise, research and development, material processing, well-equipped production facilities, and qualified staff, all of which generate costs and eventually bring up the final product’s price.

Maintenance

The safety of horses during transportation depends not only on the trailer’s safety features such as the SafeTack design and SafeKick system but also on its technical condition. Every trailer requires specific maintenance and frequent checks to ensure it’s in perfect condition and fully roadworthy. The best horse trailers are also easy to maintain and reliable enough to demand low maintenance costs.

Aesthetics

This is one factor that is usually neglected a lot. A trailer’s aesthetics are also not directly related to its rigidity and safety, but a modern appeal, precise details, and specific small touches usually speak of the manufacturer’s dedication to creating a top-quality product.

Design

Creating a safe horse trailer design requires extended knowledge, years of head-on experience, and a constant drive for improvement. It all starts with developing a sturdy frame and a spacious, lightweight, and flexible structure that often comprises several types of materials.

The Crucial Role of Horse Trailers

From their inception in the 1950s, horse trailers have revolutionized equine transportation. Their central mission remains consistent: ensuring a seamless, safe, and comfortable journey for both horses and their handlers. Modern horse trailers achieve these goals thanks to cutting-edge technological innovations, state-of-the-art design, and the use of robust yet lightweight materials.

Using the correct resources and supplies to build a horse trailer from the ground up plays a major role in the rig’s functionality and longevity. The right materials determine a trailer’s rust resistance, load capacity, road stability and handling, accident safety, and plenty of other aspects. Even the best horse trailer design will never work if the final result is compromised due to materials with poor quality or mediocre fabrication work. A horse trailer with a solid construction that comprises the right materials can be an amazing investment: quality-built horse trailers can last 25-30 years when maintained correctly, sometimes even more.

Make an Informed Purchase With the Right Horse Trailer Materials

Buying a horse trailer equipped with a comprehensive understanding of horse trailer materials is crucial. The ideal materials can vary based on the trailer's size, capacity, layout, and features, as well as your personal preferences, intended use, and specific requirements. The perfect horse trailer should offer the best value for money, encompassing usability, comfort, safety, and durability. In the contemporary horse trailer market, finding a model that ticks all the boxes and even custom-order it to cater to your every specification is feasible.