Quality Assurance: Excel in Horse Trailer Manufacturing

In the world of equine transportation, quality assurance in horse trailer manufacturing stands as the sentinel of safety, reliability, and excellence. Quality assurance (QA) is a systematic process that ensures the quality of a particular production process and the finished products. Have you ever wondered about the detailed process behind the robust, sleek trailers that securely transport our equine companions? This process is executed with precision, ensuring each aspect aligns with quality and reliability. This article navigates through the diverse aspects of Quality Assurance in Horse Trailer Construction, unveiling the stages, best practices, key performance indicators, and much more. It highlights the importance of adherence to regulations, ensuring the trailers not only embody excellence but also prioritize safety and compliance.

As we delve into this topic, the article serves as a guide, brightening the path of understanding, ensuring every aspect of horse trailer manufacturing aligns with assurance, quality, and excellence. Embark on this exploration and let the dimensions of quality assurance in horse trailer manufacturing unfold, ensuring your horses travel with safety, comfort, and elegance.

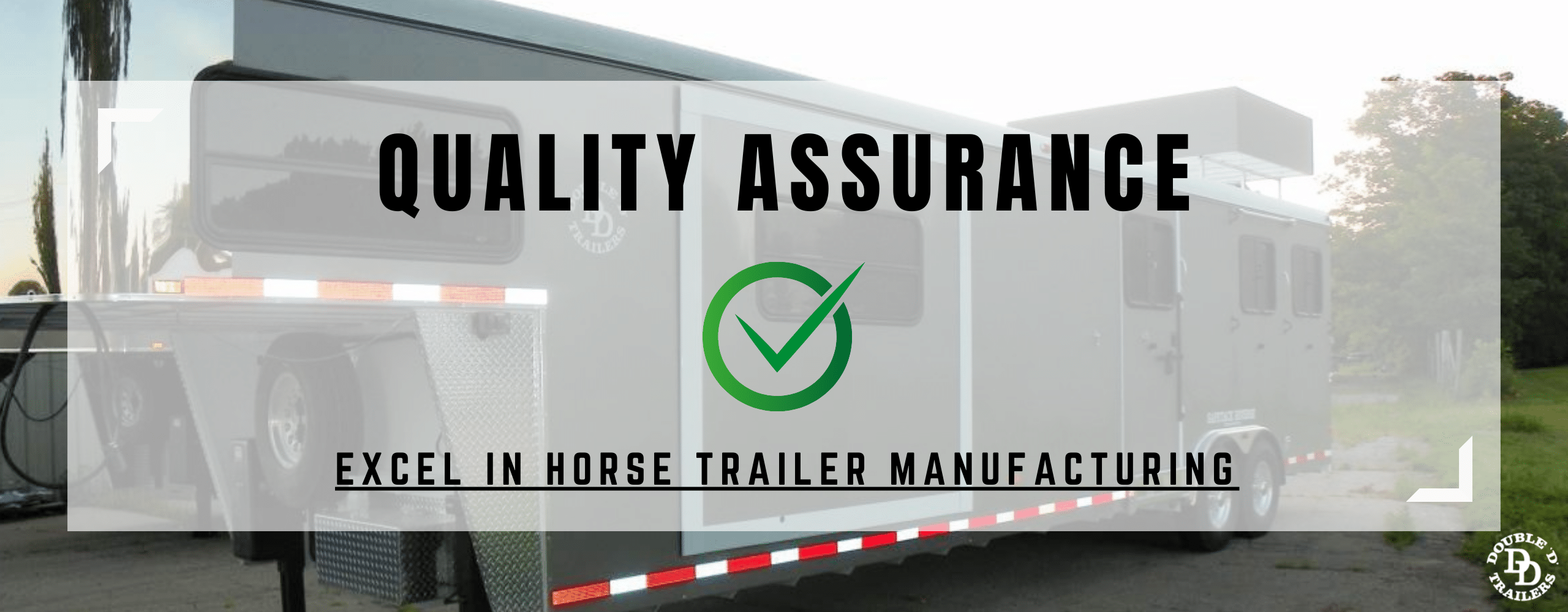

Stages of Quality Assurance in Horse Trailer Construction

There are four main stages of quality assurance in horse trailer construction: planning, implementing, checking, and adjusting. Embarking on the journey of horse trailer manufacturing is akin to ensuring a safe and comfortable home for horses on the move. The process is intricate, and the assurance of quality is paramount.

Let’s delve into the four pivotal stages of quality assurance in horse trailer construction, each ensuring the ultimate safety, comfort, and reliability of the trailer.

1. Planning: Laying the Groundwork

This phase involves meticulous planning. The cornerstone of Quality Assurance (QA) is firmly planted in the project design. It's not just about aesthetics and dimensions; it's about ensuring every design element resonates with the prevailing industry and regulatory standards. This stage is about foresight – anticipating and navigating potential challenges to ensure the seamless execution of subsequent stages. Are the designs in harmony with the latest safety regulations? Is the planned structure robust enough to ensure the utmost safety and comfort for the horses? These are the questions that guide the planning phase, setting the tone for excellence and precision in the manufacturing process.

2. Implementing: Bringing the Plan to Life

In transitioning into the implementation phase, the focus sharpens on material selection and adherence to planned fabrication steps. It's about ensuring that every nut, bolt, and piece of metal or material used aligns with the stringent criteria set forth. The implementation phase is the embodiment of the plan, where every action taken is a step towards realizing a horse trailer that stands the test of time, ensuring durability, safety, and comfort.

3. Checking: Ensuring Perfection

The checking phase shines the spotlight on inspection and testing. It's not a cursory glance over the finished product but a thorough and rigorous examination. Every inch of the trailer is scrutinized, every feature tested, to ensure it meets the high standards set. This phase is the gatekeeper, ensuring that only trailers of the highest quality and safety standards move forward, guaranteeing peace of mind for manufacturers and buyers alike.

4. Adjusting: Fine-Tuning to Excellence

The journey doesn’t end at inspection. The adjusting phase is about refinement and perfection. Any aspect of the trailer's fabrication that doesn’t meet the gold standard is meticulously fine-tuned. It's about ensuring that every trailer that rolls out is not just a product but a testament to unmatched quality and safety standards. This phase solidifies the commitment to delivering only the best, ensuring that every horse trailer is a beacon of safety, comfort, and reliability.

Best Practices and Methods for Quality Assurance

Best practices for quality assurance involve benchmarking, business process re-engineering, and cost-benefit analysis. Ensuring the pinnacle of quality is not just a goal in the realm of horse trailer manufacturing. It's a journey paved with best practices and robust methods that stand as the sentinels of quality assurance. As we transition from understanding the main stages of quality assurance, let's embark on exploring the pivotal practices and methods that fortify the bastions of quality in horse trailer manufacturing.

Benchmarking: Setting the Gold Standard

Benchmarking in the world of quality assurance is the compass that guides manufacturers to excellence: it's not just about comparisons; it's about learning and evolving. By meticulously comparing products or processes with industry leaders, a new echelon of quality is set. It’s about gleaning insights from the best in the industry and infusing those learnings into the manufacturing process, ensuring every horse trailer crafted is a beacon of quality, safety, and innovation.

Business Process Re-engineering (BPR): Elevating Operational Excellence

Business Process Re-engineering (BPR) is a strategic overhaul of a company's existing processes to boost efficiency, cut costs, and elevate quality. It’s not just about making minor adjustments; it's about completely transforming the way a business operates to ensure optimal performance and results. BPR acts as the architect of streamlined and efficient processes, meticulously designing each aspect to ensure seamless operation and the highest standards of quality. It's about synchronizing every element of the manufacturing process, ensuring each part works together cohesively, driving the enterprise towards unmatched quality and excellence.

Cost-Benefit Analysis: Balancing Quality and Expense

Cost-Benefit Analysis is a critical evaluation tool that meticulously assesses the relationship between the costs and benefits of a project or decision. It stands guard, ensuring that the pursuit of unmatched quality is harmoniously balanced with judicious expenditure. This analysis ensures that every dollar invested in the quest for quality translates into tangible, exceptional results, making the journey not just one of excellence but also of economic wisdom and sustainability. It's about making sure that the path to impeccable quality is paved with strategic, cost-effective decisions, ensuring the ultimate goal of quality assurance in horse trailer manufacturing is achieved without financial strain.

As we delve deeper into the world of quality assurance in horse trailer manufacturing, the significance of these best practices and methods becomes increasingly paramount. They are the pillars that uphold the edifice of quality, ensuring every horse trailer manufactured is not just a product but a masterpiece of quality, safety, and reliability. As we continue to navigate this path, stay engaged as we explore examples of quality assurance, each facet contributing to holistic excellence and safety in horse trailer manufacturing.

Examples of Quality Assurance in Manufacturing

As we delve deeper into the topic of quality assurance, let’s highlight two real-world examples. These instances provide a practical perspective, demonstrating the tangible implementation of quality assurance in the manufacturing landscape.

Standard Operating Procedure (SOP): Minimizing Errors

The Standard Operating Procedure (SOP) stands as a sentinel of consistency and quality. It’s not just a set of guidelines; it’s a compass that navigates the manufacturing process towards minimized errors and enhanced quality. By establishing a structured and detailed framework, SOP ensures every step of the manufacturing process resonates with precision, consistency, and excellence, crafting horse trailers that epitomize quality and reliability.

Monitoring Machine Performance and Live Data: Proactive Quality Assurance

Beyond SOPs, the realm of quality assurance is enriched with proactive strategies like monitoring machine performance and live data. It’s a window into the heartbeat of the manufacturing process, offering real-time insights into machine performance. This vigilant monitoring prevents production and assembly hiccups, showcasing potential restricted performance in real-time. It allows for preliminary maintenance and fault detection, ensuring the machinery’s optimal performance is uninterrupted and the manufacturing process flows seamlessly, echoing quality at every turn.

As we explore these tangible examples of quality assurance in manufacturing, the narrative of quality, safety, and reliability continues to unfold. These examples are not just strategies; they are the building blocks that construct the edifice of exceptional horse trailer manufacturing. They ensure that every horse trailer that rolls out of the manufacturing unit is a testament to unmatched quality, safety, and innovation. Yet, the exploration doesn’t pause here. In the next section, we’ll explore the key metrics and indicators that measure and ensure the unwavering commitment to quality in horse trailer manufacturing.

Key Performance Indicators for Quality Assurance

Key Performance Indicators (KPIs) serve as the beacon that guides the journey towards unwavering quality assurance in horse trailer manufacturing. Effective KPIs are more than just numbers. They are central to quality assurance, filled with value and easily measured, always in tune with the company's broad goals. They keep the manufacturing process on track, ensuring each step taken is a move towards top quality and innovation. As we delve deeper into the world of quality assurance, let’s explore the pivotal role of KPIs.

Acceptable Delivery Speed

Timely delivery holds its own significant place as a key performance indicator. It's not just about building the best horse trailers but also ensuring they reach customers as promised. This punctuality underscores dedication to excellence and customer satisfaction, showing clients they can count on consistent and reliable service.

Low Defect Rate

A low defect rate, where product flaws are nearly nonexistent or kept within an acceptable range, stands as clear evidence of this steadfast commitment to high-quality production.

Production Schedule Attainment

Staying on schedule is another crucial aspect. Ensuring the pace and efficiency of production align with planned schedules and company benchmarks demonstrates a smooth and effective manufacturing process. It's about making sure every part of the operation moves together cohesively, keeping projects on track and customers happy.

As we navigate the path of quality assurance with the guidance of KPIs, the commitment to delivering horse trailers that epitomize quality, safety, and reliability is reinforced. Yet, the exploration of quality assurance continues to unfold as we transition to understanding the distinction and interplay between Quality Assurance and Quality Control.

Quality Assurance Vs. Quality Control

Quality Assurance and Quality Control stand as essential components ensuring the highest standards of quality in horse trailer manufacturing. Though they share a common goal, each has a unique role in ensuring every horse trailer epitomizes excellence, safety, and reliability.

Quality Assurance (QA): The Proactive Approach

Quality Assurance is a proactive approach embedded in the design and construction processes from the start. It’s not just a stage; it’s a continuous journey that permeates every aspect of manufacturing, aiming to guarantee outstanding results. It’s the dedication to ensuring excellence is not just achieved but is a consistent and inherent feature of every horse trailer manufactured.

Quality Control (QC): The Final Check

Conversely, Quality Control acts as the final check, coming into play once the product is complete. It’s the ultimate stamp of approval, ensuring the achieved excellence is evident in every part of the finished horse trailer, ready to be delivered to the client with pride and assurance.

The Harmonious Interplay Between QA and QC

While Quality Assurance and Quality Control are distinct in their approaches, both work together in a balanced interaction, each enhancing the other, ensuring every horse trailer produced is not just a product but a symbol of quality, safety, and innovation.

Now that we’ve covered the fundamentals of quality assurance in horse trailer construction, let’s focus on some practical tips that you can apply when you next shop for a high-quality horse trailer.

How to Check for a Manufacturer's Quality Assurance Processes: 10 Tips and Pointers

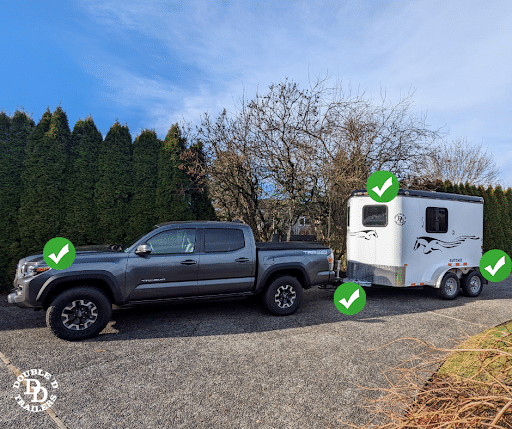

If you’re looking to buy a horse trailer, focusing on quality assurance is crucial in ensuring your trailer is safe, reliable, and excellent. When comparing horse trailer manufacturers, make sure you choose one that is committed to unwavering quality assurance. Here’s a straightforward guide with 10 tips to help you identify a horse trailer manufacturer’s dedicated QA efforts.

1. Verify Certifications

Start by checking a manufacturer's affiliation with reputable organizations like ISO (International Organization for Standardization) or NATM (National Association of Trailer Manufacturers). This affiliation confirms their steadfast commitment to high-quality assurance standards.

2. Inquire About Quality Assurance Processes

If QA policies or certifications aren’t obvious, don’t hesitate to ask about the company’s current quality assurance standards. You deserve to know that you’re choosing a manufacturer committed to excellence.

3. Request Inspection Reports

Dive into inspection reports and analyses. Quality assurance relies heavily on careful monitoring and documentation. Make sure to ask for these reports to confirm the manufacturer’s commitment to quality in every aspect.

4. Seek Consistency

Quality should be a constant in manufacturing. Confirm that the horse trailer manufacturer maintains a steady effort to uphold and monitor quality, setting them apart in the industry.

5. Gauge Staff Expertise

Evaluate the expertise and training of the staff involved in horse trailer manufacturing. This step helps determine whether the team building your trailer possesses the necessary skills.

6. Explore Equipment Maintenance Practices

Ask about the manufacturer's equipment maintenance practices. This question reveals their dedication to ensuring every machine works efficiently and reliably throughout the fabrication cycle.

7. Observe Response to Defects

Find out how the manufacturer handles product defects. Beyond the factory warranty, make sure recurring defects lead to adjustments in the supply and fabrication processes.

8. Navigate Through Product Reviews

Let the feedback from clients inform your decision. Go through product reviews to ensure you choose a manufacturer with positive feedback and a commitment to excellence.

9. Consider Communication

In horse trailer manufacturing, clear and responsive communication is essential. Ensure the manufacturer’s communication is clear, responsive, and understanding, making your journey to acquiring a new custom trailer smooth and enriched.

10. Look for Continuous Improvement and Innovation

Choose a manufacturer dedicated to continuous improvement. This commitment reflects their journey on the constant learning curve, combining tradition with the embrace of new technology and materials.

As a leading innovator in horse trailer manufacturing, Double D Trailers will soon launch the SafeTack Reverse Carbon model. This recent advancement seamlessly blends our patented SafeTack Reverse technology with the sustainable engineering of 3-D printing.

As you continue to explore quality assurance in horse trailer manufacturing, let these tips and pointers guide your path, ensuring every step resonates with the commitment to aligning with a manufacturer dedicated to unwavering quality, safety, and excellence.

Regulatory Compliance in Horse Trailer Manufacturing

Quality assurance has another primary function in addition to the ones already listed: to confirm that all products designed, fabricated, and sold by horse trailer manufacturers in the U.S. comply with all local, interstate, and national regulatory requirements. The stamp of government approval separates the reputable, trustworthy horse trailer manufacturers from the rest.

Still, regulatory compliance is tough to achieve, as it requires permits, licenses, patents, and other documentation related to production facilities, staff members, product design, material processing, and dozens of other aspects.

Important U.S. Regulations for Horse Trailer Manufacturers

Several important U.S. regulatory authorities have set guidelines and advisories regarding horse trailer manufacturing and exploitation, as follows:

- International Organization for Standardization (ISO)

- National Association of Trailer Manufacturers (NATM)

- National Highway Traffic Safety Administration (NHTSA)

ISO 9001 Certification

ISO 9001 is an international quality management system (CMS) that’s accepted as a standard across the globe and applied to products and services of all sorts, including horse trailers. For a horse trailer to be ISO-certified, the relevant ISO certification body needs to audit the manufacturing process and the entire management system of the company. Once certified, its quality becomes undisputed in 160 countries worldwide.

NATM Compliance Indicators

For over three decades, the NATM has represented manufacturers when new regulations, requirements, and standards are implied by all related authorities and government bodies. The NATM also strives to improve horse trailer safety through its Compliance Verification Program, which ensures all NATM members’ manufacturing processes comply with the Federal Motor Vehicle Safety Standards (FMVSS).

NHTSA Safety Standards

The National Highway Traffic Safety Administration has a primary focus on preventing road accidents leading to injuries and lives lost. The NHTSA’s policy prevents them thanks to safety standards enforcement, research, and education.

In essence, adherence to these regulatory standards is not just a legal obligation but also a testament to a manufacturer's commitment to safety, quality, and customer satisfaction. As consumers, understanding these regulations empowers informed decisions, ensuring that their chosen horse trailer stands up to the highest industry standards.

An Overview of Horse Trailer Regulations

Navigating horse ownership and transportation brings forth a set of regulations and specific horse trailer safety standards. These rules act as a guide for using a horse trailer, where horse owners, handlers, and transporters share the responsibility to adhere to all federal rules and trailer laws, along with following the advice of trailer manufacturers. This commitment ensures the horse trailer meets current safety standards and requirements.

Licensing and Documentation

Before hitting the road with a horse trailer, make sure to obtain the necessary licenses, permits, and approvals. These documents affirm the individual's legal authority to haul the trailer, ensuring every journey begins with assurance and legality.

Weight Restrictions

Each trailer has a specified Gross Vehicle Weight (GVW), indicating the maximum allowable weight when fully loaded. Pay attention to this number to ensure optimal performance and safety, allowing the trailer to operate efficiently on every road.

Technical Requirements

A horse trailer must be in top condition to be considered legally roadworthy. This includes the following:

- Hitch System: Ensure a secure connection between the trailer and towing vehicle for strength and reliability.

- Exterior Lighting: Maintain proper lighting to ensure visibility and signal intentions to fellow travelers on the road.

- Braking System: Ensure efficient brakes for safely halting the trailer, especially in emergencies.

- Axles and Tires: Regular inspection is crucial to ensure they are robust and ready to bear the weight and stresses of transportation.

- Breakaway System: Ensure the trailer can halt autonomously if it detaches, preventing a runaway hazard.

Gross Vehicle Weight Rating (GVWR)

GVWR (Gross Vehicle Weight Rating), also known as Gross Vehicle Mass (GVM) represents the maximum allowed weight of a vehicle or trailer, including its own mass, equipment, fluids, optional systems, passengers, and load.

GVWR matters in horse trailer building because manufacturers always strive to keep it as low as possible producing durable and long-lasting structures and designs. As a prospective buyer, this limit is crucial when choosing a horse trailer, ensuring it aligns with the tow vehicle's GVWR.

Federal Motor Carrier Safety Regulations (FMCSR)

The Federal Motor Carrier Safety Regulations (FMCSR) is a set of specific rules aimed at reducing vehicle accidents. These rules outline the standards for vehicles and trailers on the road, focusing on those intended for commercial use and load transportation.

For non-commercial horse transportation, the Federal Motor Carrier Safety Administration (FMCSA) has created a specific regulation. When no compensation is involved in horse transportation and the driver is not part of a commercial transportation entity, the FMCSRs are not applicable, providing clear and straightforward guidance for every journey.

Take the Reins: Ensuring Quality Assurance in Horse Trailer Manufacturing

In horse trailer construction, Quality Assurance (QA) plays a pivotal role, ensuring excellence, safety, and reliability throughout the process. The stages of planning, implementing, checking, and adjusting are fundamental, providing a solid base for a smooth manufacturing journey. Best practices and methods for QA, including benchmarking, business process re-engineering (BPR), and cost-benefit analysis, ensure that products and processes align with industry standards, refine existing processes, and maintain a balance between efforts and expenses.

Examples of Quality Assurance in manufacturing such as standard operating procedures and monitoring machine performance, safeguard consistency and quality, minimizing errors throughout the manufacturing process. Key performance indicators or KPIs like acceptable delivery speed, low defect rate, and production schedule attainment highlight efficiency, quality, and timeliness, ensuring the production of robust horse trailers.

In understanding Quality Assurance vs. Quality Control, the distinction is clear: QA is a proactive guardian from the start, while Quality Control confirms excellence in the finished product. The 10 tips and pointers we’ve provided for checking a manufacturer's QA processes ensure transparency and commitment to quality. Familiarizing horse trailer regulations, understanding the Gross Vehicle Weight Rating (GVWR), and adhering to the Federal Motor Carrier Safety Regulations (FMCSR) all contribute to compliance, safety, and roadworthiness, ensuring every horse trailer stands as a symbol of quality, safety, and excellence.

Take the reins, embark on the journey, ensure Quality Assurance in horse trailer manufacturing, and let every road traveled whisper tales of excellence, safety, and reliability.

Watch How Double D Trailers Are Built From the Ground Up!